Rockwell Hardness Test Marks On Lincoln Cents

By Pete Apple

The correct degree of hardness is a critical factor in the minting of coins. If an unstruck planchet is too hard the image pressed on the coin will not be clear. If it’s too soft, the coin will wear too quickly. The U S Mint uses a Rockwell Hardness Test on all raw coin material (including copper- plated zinc blanks). (US Mint, E-mail 8/24/2015, Diamond, 2006, Page 16).

The test procedure involves pressing a 1/16″ metal ball into the coin material with a known amount of pressure and measuring the depth of penetration. There are other Rockwell Scale Protocols for harder materials where either a different sized ball or a spheroconical diamond is used to make the indentation. The Scale Protocol currently used for coin material involves the lightest pressure that can be used by a Rockwell tester.

Specifically,

“…the Rockwell test makes two depth measurements. The ball (say) is brought in contact with the material to be tested. The preliminary force is applied for a set length of time, and then the depth of the indentation is measured. Then the force is increased in a set rate until it reaches the total force. This force is kept constant for a predetermined period, after which the force is reduced to the preliminary force level. After a set period of time, the depth of the indentation is measured for a second time. Usually the entire process is carried out by automatic machinery.

The Rockwell hardness is calculated from the difference between the depth of the indentation after the application of the total force and its initial depth under the preliminary force. Call this difference, in millimeters, h.” (Sizes, 8/12/2015)

The Superficial Rockwell Hardness Number equals one hundred minus the fraction h over one thousandth of a millimeter. {R15T# = 100-(h/0.001)}.

The U S Mint currently uses the Superficial Rockwell 15T measurement protocol. (Concurrent Technologies Corporation, Page 40) This protocol uses Preliminary Force = 29.42N (3 kgf) and Total Force = 147.1N (15kgf).

(N = Newton; 1 Newton is the force needed to accelerate 1 kilogram of mass at the rate of 1 meter per second squared. kgf = Kilogram-force. It is equal to the magnitude of the force exerted by 1 kilogram of mass in the average magnitude of gravity on earth).

While this paper focuses on Rockwell Tests on planchets, it should be acknowledged that Rockwell Tests are also performed on dies and on master hubs. “A die that is too hard will be brittle and have a tendency to fail prematurely. A die that is too soft will deform and deteriorate too quickly.” (Diamond, Page 16) A die which has had a Rockwell Test will leave a raised bump on the coin. This same source shows a photo of a 2000 Lincoln Cent with a small, circular indentation just above Lincoln’s bow tie. It has been proposed that this is from a Rockwell Test on a Master Hub since the same mark can be seen in preceding and subsequent years without change in position. However, it should be noted that neither such a circular indentation from a Test on a Master Hub nor a raised bump from a Test on a Die will leave a “mirror image” of the indentations on planchets being discussed here. The shapes of these indentations will be different. (See a discussion of this in Appendix A).

Planchets with Rockwell Test Marks are very rare to extremely rare. (Harper and Miller, Page 62.) “Dies and planchets tested in this fashion are supposed to be discarded, since they are blemished once the procedure is completed. If they are not discarded, then you have a desirable die error and planchet error, respectively.” (Diamond, Page 16)

There is a notable lack of consensus in the Numismatic Community over whether there are actually any legitimate Rockwell Test Marks on coins. Absolute certainty requires that the test itself be witnessed and the planchet followed through the complete minting process!

There are, however, some accounts of coins with alleged Rockwell Test Marks. “Rockwell test marks applied to planchets before the strike are recognized among some U.S. coins. At the time they wrote their book, Steiner and Zimpfer (1975) recognized such errors as the exclusive output of the San Francisco Mint. They list cents (business strikes and proofs) and proof half dollars. Elsewhere I have read that such errors are largely or exclusively restricted to S-mintmark cents from the early 1970’s (I can no longer remember the source, however).” (Diamond Page 17; Steiner and Zimpfer, pp. 122-123.)

This same source shows an image (shown below with permission) of an alleged Rockwell Test Mark in planchet on a 1971-S Lincoln Cent.

Figure 1

Figure 1

This was authenticated as a Rockwell Test Mark by “Lonesome” John Devine. The author states that this example is convincing.

“The floor of the cup-shaped depression is completely smooth, as would be expected of a dimple produced by a pin tipped by a small steel ball. Although there is no metal flow in the design bordering the crater, there is also no trace of a pressure ridge, indicating that the defect was present before the strike. The pit is oval, rather than circular, but this can be attributed to distortion produced by the strike. There is always the chance that such a defect could be the result of a struck-in or rolled-in piece of debris that fell out after the strike. But the smooth texture of the pit and its central location provide a strong argument in favor of a Rockwell test mark.” (Diamond, Pages 17 – 18)

“Lonesome” John Devine, who died in 2013, was a highly respected error coin pioneer. He was a founding member of the Combined Organizations of Numismatic Error Collectors of America (CONECA) and the first inductee into the CONECA Hall of Fame. He created the Error Coin Museum, which was the umbrella under which the Collectors of Numismatic Errors (CONE) and the Numismatic Error Collectors of America (NECA) were able to merge into CONECA in 1983. (Fern and Potter, July 30, 2013)

This description provides a working definition of how a Rockwell Test Mark in planchet is to be recognized. I would add the notation that the depression would appear more hemispherical if it were not located adjacent to devices which contribute to its elongation. Otherwise, there is minimal distortion of the mark by the strike, as can be seen by observing the shape of the mark on the East/West axis.

I would also add that there must be no bulge on the opposite face. Such a bulge would indicate the use of greater pressure than a Rockwell Test allows. Even if it were from a Rockwell Test such an “anvil effect” would indicate that too much pressure had been used and the resulting Rockwell Number would likely be inaccurate. (Low, Samuel R. III, Page 5) Such a bulge would also have occurred after minting, since the minting press would likely remove most traces of a bulge made before minting.

The composition of the Lincoln Cent (except for 1943 when the cent was zinc coated steel) up to 1962 was 95% copper and 5% tin and zinc. In 1962 the cent’s tin content, which was quite small, was removed. This alloy of 95% copper and 5% zinc remained until 1982 when the composition was changed to what is commonly called copper plated zinc. Cents of both compositions appeared in 1982. This alloy from 1982 to the present is actually Zinc Alloy 190 electroplated with 8 microns of copper. (Concurrent Technologies Corporation, Page 1, Section 1.1) ALLOY 190: COMPOSITION (% by Weight) Lead = 0.005 max; Iron = 0.010 max; Cadmium = 0.005 max; Copper = 0.7 to 0.9; Zinc = Balance. (Jarden Zinc, 8/12/2015)

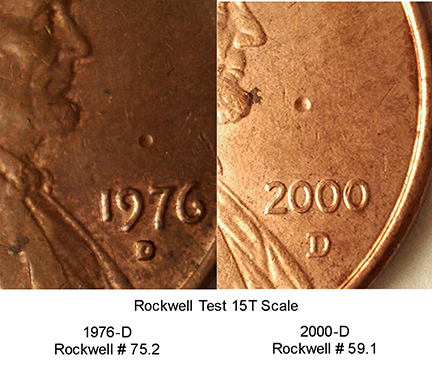

A comparison of the hardness of Lincoln Cents minted before 1982 and after 1982 yields some interesting results. The copper alloy used in pre-1982 cents is 45 on the Rockwell B Scale. (Olin, 9/3/2015) This converts to 76 on the 15T scale. (England, 9/1/2015) Conversion tables are known to be reasonably accurate, but not 100%. (Dusharme, 9/2/2015; Low Page, 13) The actual 15T Rockwell Hardness on this 1976D was measured at 75.2 (Figure2). (See Acknowledgements for sources of Rockwell Testing mentioned in this paper).

Figure 2

Figure 2

“Hardness between 62 and 72 Rockwell 15T are [sic] considered nominal (standard) for RTS Zinc planchets at the United States Mint.” (RTS= Ready to Strike). (Concurrent Technologies Corporation, Page 42) The actual value on this 2000-D was measured at 59.1. In Figure 2, it can be seen that the indentation on the 2000-D cent is slightly larger and deeper than the indentation on the 1976-D cent. This is due to the softer material. Even though the zinc-based coin is significantly (21%) softer than the copper-based coin, the actual effect on the indentations is modest.

With regard to the Rockwell test mark authenticated by “Lonesome” John Devine, (Figure 1), the indentation appears larger than the indentations illustrated in Figure 2. My suspicion is that the U S Mint used the Rockwell B Scale for tests prior to 1982. Using the B Scale is not recommended for copper alloys unless the thickness is greater than 1 mm. (Materion Corporation, Page 1) Lincoln cents minted before 1982 have a thickness greater than 1.5 mm.

The following comparison images are instructive (Figure 3). The two images are overlays of Rockwell test marks on the obverse design placed over the reverse design to show how the dimples might appear on the Memorial columns. These same images without overlays may be seen in Figure 4. It should be noticed that the diameter of the indentation on the John Devine authenticated coin is slightly less than that on the Rockwell B Scale indentation. I believe that the reason for the difference in diameters is due to the effect of the strike on the indentation. The strike reduces the size of the diameter.

Figure 3

Figure 3

I should note that the U.S. Mint disagrees with my speculation that the Rockwell B Scale was used for tests on Lincoln cents prior to 1982. I informed the Mint of my suspicion and received this response:

“No, actually Hardness 15T Scale was used prior to 1982, as well as currently. We believe the only coin that used the Rockwell Hardness B Scale was the 40% silver (silver clad) Kennedy half dollar from 1965 – 1970.” (U S Mint, E-mail 9/17/2015)

If this response from the Mint is correct, then it is improbable that the indentation in the 1971-S cent is a Rockwell Test Mark.

Rockwell B Scale is typically used with copper alloys. Use of the C scale on Lincoln cents produces an anvil effect (a raised area on the opposite side of the coin) and leads to inaccurate Rockwell Number readings.

The respective Scale pressures are (Low, Table 1):

Rockwell C Scale: Preliminary Force = 98.07N (10 kgf) Total Force = 1471N (150kgf)

Rockwell B Scale: Preliminary Force = 98.07N (10 kgf) Total Force = 980.7N (100kgf)

Rockwell 15T Scale Preliminary Force = 29.42N (3 kgf) Total Force = 147.1N (15kgf)

Here is a comparison of images of indentations produced by the 3 scales:

Figure 4

Figure 4

The current hardness range specifications for Lincoln Cents minted after 1982 is slightly higher than that for Cupronickel (the Incumbent Material for 5-cent coins) and even higher than that for Cupronickel-Clad C110 (the Incumbent Material for Quarter Dollar Coins). (Concurrent Technologies Corporation, Pages 43-44) Lincoln cents are currently harder than nickels and quarters!

The company that supplies zinc planchets to the U S Mint, Jardin Zinc, does Rockwell Hardness Tests on their Rolled Zinc Strip (Jardin, 8/12/2015) and on blank planchets before shipping where customer specifications require that it be done. (Jardin Zinc Sales 8/14/2015).

I talked with a person at Concurrent Technologies Corporation, the company that did the Alternative Metals Study for the U S Mint. He said that a Rockwell test mark on a zinc planchet will still be visible after a coin is struck on that planchet. He says that it will probably be altered somewhat, but it is impossible to say exactly how because too many other factors are involved.

We are accustomed to thinking that if an imperfection on a coin satisfies the diagnostics associated with a particular mint error, then we can assign it to that mint error. For example, a cud (marginal die break) is unlikely to be confused with any other defect. In other words if it looks like a duck, walks like a duck, and quacks like a duck, then it is a duck!

However, with a Rockwell Test Mark, this way of thinking may not be appropriate. It may be possible for an indentation to match the description of a Rockwell Test Mark without actually being a Rockwell Test Mark. The only way I know to be certain that a mark came from a Rockwell Test is to have actually witnessed the test which, of course, is not possible! The most we can say is that a particular indentation meets the expectations of a Rockwell Test Mark. A Rockwell Test Mark should have a smooth, hemispherical cross section profile and assume the shape of a circle or an oval (if it is adjacent to a device). There should be no anvil effect (a raised area on the opposite side of the coin) and no pressure ridge around the circumference of the depression.

I now introduce 2 coins (found while coin roll hunting) that we can analyze as to whether the indentations found on their surfaces qualify as potential Rockwell Test Marks. One is a 2000-D Lincoln Memorial Cent with one indentation on the reverse (Figure 5). The other is a 1995-D Lincoln Memorial Cent with two indentations on the Reverse (Figures 6 & 7).

Figure 5

Figure 5

Even though the indentation on the 2000-D cent appears to be the correct size and shape, a detailed examination appears to show a pressure ridge around the circumference. Therefore this cannot be a Rockwell test mark.

The other cent with indentations is a 1995-D Lincoln Cent with 2 indentations of the same size:

Figure 6

Figure 6

Figure 7

Figure 7

These indentations seem to show the correct shape for a hardness test mark. As was observed in the 1971-S cent authenticated by John Devine, the diameter of the indentation may be slightly smaller than the indentation on the reference coin, due to some “closing up” during the strike. I notice that the indentation to the right of the Memorial has a slight elongation (East/West) towards the last column of the Memorial, as would be expected with a Rockwell Test Indentation.

I know the odds are low that a Rockwell Test Mark will make it through the minting process. I am also thinking that the odds are low – or even much lower – that a random contact mark on a coin

• would have the same hemispherical cross-sectional profile as a Rockwell Test Mark AND

• show the same depth as a Rockwell 15T test mark AND

• have the same diameter as a Rockwell 15T test mark (adjusted for the strike) AND

• not leave a pressure ridge AND

• not leave an anvil effect (bulge) on the opposite side of the coin.

I know of no way to calculate the probability of all those things occurring as a result of random post-mint damage – but I think it would be astronomical. It would be even more improbable for all these things to occur twice on the same coin as the result of random post-mint contact, as appears on this 1995-D. On the other hand, Rockwell Testing Protocol does suggest that an object be tested at least twice so the results can be averaged.

“Because of the relatively small volume of material affected by the hardness test, care must be taken to obtain representative test data. Several measurements should be taken to avoid a false reading caused by microstructural inconsistencies such as hard beryllide particles or grain boundaries. Hardness should be checked on cross sections when nonuniform cold work causes high surface hardness. The depth of penetration of the indenter must be less than 10% of the metal thickness, and the reading must be taken at least two indenter diameters from an edge.” (Materion Corporation, 9/4/2015).

I am thinking that there is a high probability that these are Rockwell Test Marks on this 1995-D Lincoln Cent.

Appendix A

Another type of Rockwell Test Mark which may be found on Lincoln cents is a raised bump. If there is an indentation on a die caused by a Rockwell Test, then it would be transferred to the coin as a bump during the strike. I think it is important to understand what appearance we might expect this bump to take.

Steel for dies is supplied to the U S Mint by Latrobe Specialty Steel Company, a Division of Carpenter Technology. The steel alloys are Alloy 52100 for small diameter coins and Alloy L6 for quarter on up. They are sold in the spheroidized annealed condition to a maximum Rockwell C hardness and certified capability hardness to a minimum Rockwell C hardness level. Everything is in Rockwell C scale. This hardness range is approximately 33 to 58 Rockwell C hardness. (Carpenter Technology, E-mail 9/22/2015)

Alloy 52100 is a deep hardening steel alloy used for aircraft bearings and other high stressed parts where good rolling contact fatigue strength is required at temperatures below 400⁰F. Its typical composition is 1.05% C, 0.35% Mn, 0.30% Sn, 1.50% Cr, and the balance Fe. (Latrobe, 52100)

Alloy L6 is a versatile oil-hardening tool steel that is characterized by good toughness and is suitable for tools, dies and machine parts. Its relatively high nickel content gives it greater impact toughness. Its typical composition is 0.70 C, 0.60 Mn, 0.25 Si, 0.70 Cr, 1.40 Ni, and the balance Fe. (Latrobe, L6)

The level of hardness of these steel alloys requires testing with the Rockwell C Scale. The requirements for using this scale with this level of hardness necessitate the use of a spheroconical diamond tipped indenter. (Low, Table 1) This means that the resulting indentation will have a different conformation than the hemispherical shape discussed in this paper for Rockwell 15T Tests.

I have sketched an overlay of the Rockwell 15T 1/16″ Ball Indenter cross section imposed on a cross-sectional view of the spheroconical diamond indenter tip so that the differences may be visualized. (Figure 8) (Low, Table 1). The size of the 1/16″ ball indenter is about 4 times the size of the spherical portion of the spheroconical indenter.

Any mark on a coin thought to have originated from a Rockwell Test on a Die (where the mark on the coin would be raised) or Master Hub (where the mark on the coin would be an indentation), would need to exhibit the same shape as in this cross sectional view of the spheroconical diamond tip indenter rather than the hemispherical shape of a Rockwell 15T Test Mark. According to my calculations, once the diameter of the mark exceeds approximately 0.28 mm, the slope of the sides will no longer be curved as they would be for a hemisphere, but will be straight and sloping outward at 120⁰ to reflect the shape of the cone portion of the indenter.

Figure 8 (Low, Page 24 Section 3.3.8.1)

Figure 8 (Low, Page 24 Section 3.3.8.1)

Appendix B

Since beginning this research project, I have encountered numerous reactions proposing that some other object caused these indentations. Among the proposals for candidates: a stylus of some kind, a ball point pen, or a BB. I have attempted to take these ideas seriously and have come to the realization that a critical piece of information in considering each possibility is the nature of the geometry of the tips of these instruments.

It is simply impossible to examine the tips of the myriad styli in the world today! I think that it is simply best to observe that a stylus is a possible source. However, holding a 1/16″ ball bearing in my hand impresses upon me how tiny such a tip must be. I also wonder just how many might have a hemispherical shape. I am not aware of any stylus which meets these criteria, but perhaps there is one.

Thinking about a ball point pen is somewhat simpler. The tip of a ball point pen is approximately hyperbolic and merges into a cone. This means that an indentation made b y a ball point pen must express that same geometry. Here is a photo of the tip of a ball point pen next to a 1/16″ ball bearing. (Figure 9)

Figure 9

Figure 9

I have done a few calculations to try to see what a BB strike would need to look like. The calculations are easier if the imagery is reduced to a circle with a chord, representing the surface of the coin, cutting through it (rather than a sphere with a plane cutting through it).

The formula to calculate a chord length = 2 x the square root of (the radius squared – the distance of the chord from the center of the circle squared). (It is a lot easier, even, to use a Chord Calculation site. (Chord) I invite you to check out my math.

Imagine a sphere which makes an indentation on a blank. If it indents ½ way (a full hemisphere), then it leaves a mark with a diameter = the diameter of the sphere. If it indents ¼ (a ½ hemisphere) then it leaves a mark of approximately 2/3 the diameter of the sphere.

The caliber of a normal BB gun is 4.5 mm. The normal diameter of a BB is 4.4 mm.

For a Rockwell Ball indenter using B and 15T Scales, the diameter is = 1.58 mm (1/16″).

The diameter of many of the marks we are seeing on these Lincoln Cents is in the neighborhood of ½ to 1 mm. The depth of the mark is what translates into the hardness number and also what translates into the diameter of the mark. The strike of the die will also adjust the diameter a bit (making it smaller) and may also give it some elongation (especially when it is adjacent to a device).

For a 1/16″ Rockwell Ball Indenter, a 1 mm diameter will represent an indentation of approximately ½ of the hemisphere. This is enough indentation to leave rather steep, upward sloping, sides to the mark.

For a BB to leave a 1 mm diameter indentation, the depth of the indentation must be only about 1/20 of the diameter of the BB – which would leave an extremely shallow slope to the sides of the mark.

This means that most of the marks which have been thought to be BB strikes have sides which are too steep to be made by a BB. They are, in other words, too deep to be made by a BB and also leave only an approximate 1 mm diameter depression. The 1 mm diameter depression left by a BB strike would be almost flat! A smaller diameter mark would be even flatter and very shallow! In addition, a BB would most likely leave a pressure ridge around the circumference of the depression. It may also leave an anvil effect (raised area) on the opposite side of the coin.

I have made a crude drawing in an attempt to illustrate this. It is not exactly to scale, but I think that it is close enough so that the concept can be understood. (Figure 10)

Acknowledgements

Thanks to Mike Diamond for editing assistance.

Thanks to Bob Saylor and Pyramid Machine Shop of York, PA., for Testing with Rockwell B and C Scales.

Thanks to Mark Obstalecki, Numismatist, for Testing with the Rockwell F Scale.

Thanks to Sydney at Baseline Data in Aransas Pass, TX. He tested Rockwell 15T Scales. Here is a photo of this testing. (Figure 11)

References

Carpenter Technology, E-mail communication with a Sales Representative, Received 9/22/2015.

Concurrent Technologies Corporation, “Alternative Metals Study”, Final Report, August 31, 2012 Contract Number: TM-HQ-11-C-0049 Submitted to the U S Mint, http://www.usmint.gov/about_the_mint/PDFs/ctcr-alternative-metals-study-2012-08-31.pdf 8/12/2015.

Chord Calculation Site https://www.easycalculation.com/area/chord-length-circle.php

Diamond, Mike, “Rockwell Test Marks: The Definite and the Dubious”, ErrorScope Vol 15 No 4, July/August 2006.

Dusharme, Dirk, Quality Digest, “Hardness Testing: Absolutely Not Absolute” http://www.qualitydigest.com/april98/html/hardness.html 9/2/2015

England, Gordon, (Independent Metallurgist and Consultant to the Thermal Spray Coating Industry) Surface Engineering Forum, “Hardness Scale Conversion Table” http://www.gordonengland.co.uk/hardness/hardness_conversion_3c.htm 9/1/2015.

Fern, Ronn and Potter, Ken, “Another Error Coin Pioneer Passes … Lonesome John Devine 1933-2013”, CoinWeek July 30, 2013, http://www.coinweek.com/coins/error-coins/another-error-coin-pioneer-passes-lonesome-john-devine-1933-2013/ 9/14/2015.

Harper, David C. and Miller, Harry, U.S. Coin Digest, 11th Edition, (Krause Publications).

Jardin Zinc, “Solid Zinc” http://www.jardenzinc.com/techdata/JardenSolidZinc.pdf 8/12/2015.

Jardin Zinc Sales Rep Conversation 8/14/2015.

Latrobe Specialty Steel Company, Data Sheet, “LESCALLOY® 52100 VAC-ARC® HIGH PERFORMANCE BEARING STEEL” http://customer.cartech.com/assets/documents/datasheets/52100.pdf 9/22/2015.

Latrobe Specialty Steel Company, Data Sheet, LSS™ L6 TOOL STEEL (ASTM L6), 9/22/2015. http://customer.cartech.com/assets/documents/datasheets/LSS_L6.pdf

Low, Samuel R. III, NIST Recommended Practice Guide, National Institute of Standards and Technology, Technology Administration, U.S. Department of Commerce, Special Publication 960-5, “Rockwell Hardness Measurement of Metallic Materials” Materials Science and Engineering Laboratory January 2001. http://www.nist.gov/manuscript-publication-search.cfm?pub_id=853006 8/15/2015.

Materion Corporation, Tech Briefs, “Hardness Testing Copper Alloy Products”. http://materion.com/~/media/Files/PDFs/Alloy/Tech%20Briefs/AT0012-0311%20-%20Tech%20Briefs%20-%20Hardness%20Testing%20Copper%20Alloy%20Products.pdf 9/4/2015.

Olin Kupferlegierungen “Copper Alloy Guide”. http://olinbrass.com/sites/default/files/downloads/Olin-Brass-Mill-Products-Copper-Alloy-Guide-Metrics.pdf 9/3/2015.

Sizes, “Rockwell Hardness Scales” http://sizes.com/units/hardness_rockwell.htm 8/12/2015.

Steiner, Phillip and Zimpfer, Michael (1975) Modern Mint Mistakes (5th edition).

U S Mint: E-mail communications received 8/24/2015, 9/17/2015, and 9/29/2015.